Enclosed Motor Controls

Enclosed Motor

Controls

A-334

Data subject to change without notice.

www.weg.netMedium Voltage Starters

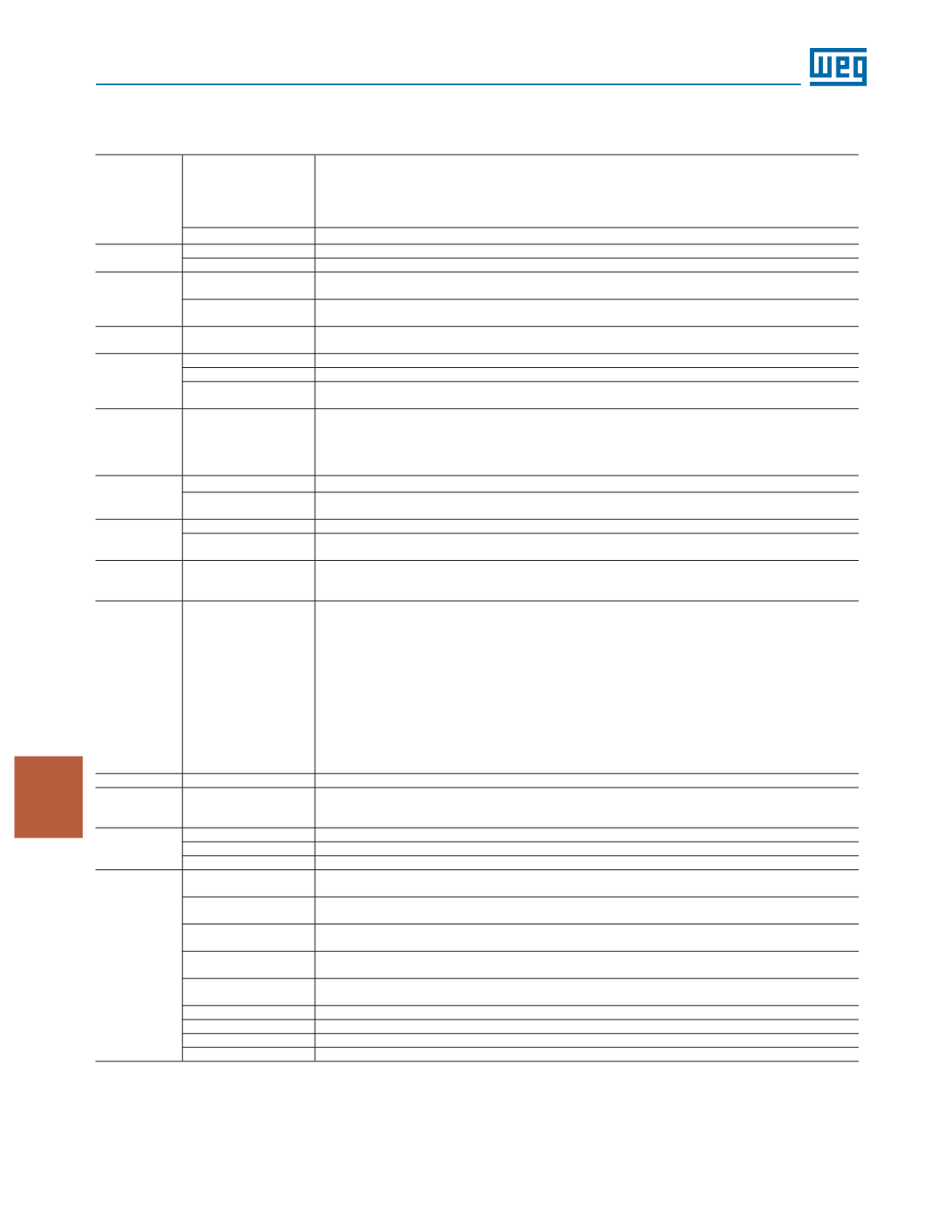

Technical specifications

Power Supply

Power Voltage (R/1 L1, S/3L2,

T/5L3)

Low voltage test:

500Vac: (-60% to +10%) or (200 to 550Vca)

Models:

2300Vac: (-60% to +10%) or (920 to 2530Vca)

4160Vac: (-60% to +10%) or (2760 to 4576Vca)

Frequency

(50 to 60Hz): (±10%) or (45 to 66Hz)

Capacity

Maximum number of starts

5 starts in 2 hours (One start every 30 minutes)

Start cycle

AC-53a; 4.5-30:50-2

Thyristors

Medium voltage SCR per

power arm

2300Vac: 2 thyristors per per power stack

4160Vac: 2 coupled pairs of thyristors

Reverse voltage peak on

the arm

2300Vac: 6.5kV

4160Vac: 13kV

Protections

Protection by

Hardware

dv/dt filter

Active overvoltage protection on the thyristors

Control Supply

Control voltage

As per code of the SSW7000: 110Vac: (-15% to10%) or (93.5 to 121Vac) 230Vac: (-15% to 10%) or (195.6 to 253Vac)

Frequency

(50 to 60Hz): (±10%) or (45 to 66Hz)

Consumption

Continuous: 900 mA

Peak: 9.5 A (during the closing of the vacuum contactors)

Control

Method

Voltage ramp.

Current limitation.

Pump control.

Torque control.

Current ramp.

Inputs

Digital

6 insulated digital inputs, 24 Vdc, programmable functions

Analog

2 differential inputs insulated by differential amplifier; Al1 resolution: 12 bits, Al2 resolution: 11bits + signal, (0 to 10) V, (0 to 20) mA

or (4 to 20) mA, Impedance: 400kQ for (0 to 10V), 500Q for (0 to 20mA) or (4 to 20mA), programmable functions

Outputs

Digital

3 NO/NC contact relays, 240 Vac, 1A, programmable functions.

Analog

2 insulated outputs, (0 to 10V) RL ± 10kQ (maximum load), 0 to 20mA or 4 to 20mA RL<500Q, 11-bit

resolution, programmable functions

Man Machine

Interface

Standard

9 keys: Turn/Stop, Increase, Decrease, Rotation Direction, Jog, Local/Remote, right Soft key and left

Soft key. Graphic LCD.

It enables access to/change of all parameters.

Safety

Main protections

Under and Overcurrent and current unbalance. Under and Overvoltage and

voltage unbalance. Under and Overtorque and Active overpower Phase

loss.

Reverse phase sequence Overtemperature in the power racks. Motor

overload. Motor overtemperature (optional). External defect.

Ground fault by voltage or current.

Fault in the power racks.

Fault in the power contactors.

Faults in the control boards.

Communication faults of MMI and between controls.

Faults in the communication networks.

Programming errors.

For further details and more protections implemented, refer to the programming manual.

Protection degree

IP41

Standard panel

PC connection for

programming

USB Connector

USB standard Rev. 2.0 (basic speed).

USB plug type B “device”.

Interconnecting Cable: standard host/device shielded USB cable

Environmental

Conditions

Temperature

-10° a 40°C

Altitude

Up to 1000 m above sea level. For higher altitudes, contact our sales force.

Humidity

Air relative humidity of 5 % to 90 % non-condensing.

Standards

NBR IEC 62271-200

High voltage controlgear and switchgear - part 200:

High voltage controlgear and switchgear in metal enclosure for voltages over 1 kV up to and including 52 kV

IEC 62271-1

High-voltage switchgear and controlgear - Part 1:

Common specifications

IEC 60060-1

High-voltage test techniques. Part 1:

General definitions and test requirements

CISPR 11

Industrial, scientific and medical (ISM) radio-frequency equipament - electromagnetic disturbance characteristics - limits and

methods of measurement

IEC 61000-4-4

Electromagnetic compatibility (EMC) - Part 4: testing and measurement techniques - section 4: electrical fast transient/burst immuni-

ty test. Basic EMB publication

IEC 61000-4-18

Electromagnetic compatibility (EMC) - Part 4-18: testing and measurement techniques - damped oscillatory wave immunity test

NBR IEC 60529

Protection rates for electric equipment enclosures (ip code)

UL 347

Medium Voltage AC Contactors, Controllers and Control Centers

UL 347B

Medium Voltage Motor Controllers