Factory Built Modifications

Data subject to change without notice.

www.weg.netParts &

Modifications

A-342

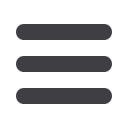

Painting

Plan

Recommended Uses

Surface

Preparation

Grade

PRIMER

INTERMEDIATE

FINISH COAT

ADHERENCE

GRADE

ASTM

Paint

Film

Thickness

(

μ

m)

Paint

Film

Thickness

(

μ

m)

Paint

Film

Thickness

(

μ

m)

D-3359

201A

Non aggressive environments;

Not recommended for direct exposure to

solvents, alkalis and acid vapors

Sa 2 ½

Synthetic

alkyd

20 – 55

-

-

Synthetic alkyd

enamel

40 – 60 3B to 5B

202E

Aggressive sheltered industrial

environments; Chemical, pulps and

paper industries, resistant to acid

steams, alkalis and solvents vapors

Sa 2 ½

Synthetic

alkyd

20 - 55

Epoxy

Isocyanate

20 - 30

Epoxy

polyamide

enamel

100 – 140 3A to 5A

202P

Aggressive sheltered or non-sheltered

industrial environments; Chemical,

mining, pulp and paper industries,

resistant to acid steams, alkalis and

solvents vapors; Indicated to food

processing motors – USA and Europe

Sa 2 ½

Synthetic

alkyd

20 - 55

Epoxy

Isocyanate

20 - 30

1 coats

Aliphatic

polyurethane

enamel

60 - 100 3A to 5A

203A

Environments low aggressiveness; Not

recommended for direct exposure to

solvents, alkalis and acid vapors

Sa 2 ½

Synthetic

alkyd

20 – 55

Synthetic

powdered

alkyd

30 a 45

Synthetic alkyd

enamel

30 – 45 3B to 5B

211E

Painting of equipment, structures in

general subject to moderate and high

aggressive level such as: pulp and paper

plants, steel and iron and chemical

industries

Sa 2 ½

Polyamide

Epoxy

90 - 130

-

-

Polyamide

Epoxy

90 - 130 3A to 5A

211P

Painting of equipment, structures in

general subject to moderate and high

aggressive level such as: pulp and paper

plants, steel and iron and chemical

industries

Sa 2 ½

Polyamide

Epoxy

90 - 130

-

-

Aliphatic

polyurethane

enamel

65 – 90 3A to 5A

212E

Non sheltered marine environment;

Resistant to acid, alkalis and solvent

spills

Sa 2 ½

Zinc ethyl

silicate

70 - 90

Epoxy

polyamide

90 – 130

Polyamide

Epoxy

90 – 130 3A to 5A

212P

Non sheltered marine environment;

Resistant to acid, alkalis and solvent

spills

Sa 2 ½

Zinc ethyl

silicate

70 - 90

Epoxy

polyamide

90 – 130

Aliphatic

polyurethane

enamel

65 – 90 3A to 5A

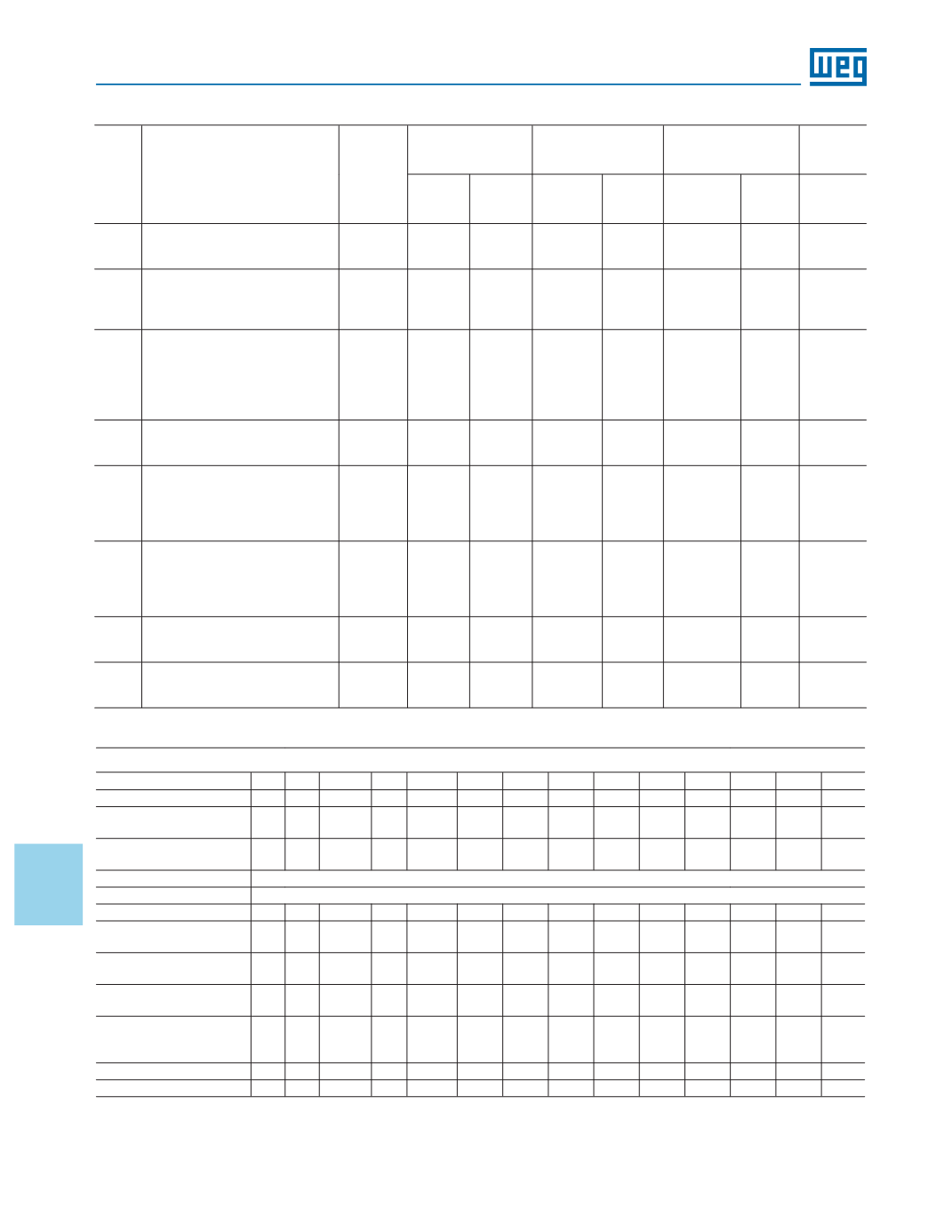

Special Shaft

NEMA FRAME SERIES

48 56

140T 180T 210T 250T 280T 320T 360T 400T 440T 500 580

IEC FRAMES SERIES

63 UP 80 90 100/112 132 160 180 200 225 250 280 315 355

Second Shaft End (standard

dimension)

n/a n/a

60

72

87

101 104 189 189 392 396 407 752 879

Threaded center hole in the

shaft end

n/a n/a

33

33

41

51

85

136 155 std

std

std

420 Stainless steel shaft end

Add 10% to motor list price

315 Stainless steel shaft end

Add 15% to motor list price

Special Shaft

Special Shaft Diameter (Type

“A” mod)

n/a n/a

58

58

87

130 151 189 209 392 396 407 752 879

Special Shaft Length (Type

“B” mod)

n/a n/a

63

63

96

113 120 208 216 446 450 473 821 987

Special Shaft Diameter &

Length (Type “C” mod)

n/a n/a

72

72 125

141 158 249 262 574 579 628 965 1117

Special Shaft Diameter,

Length & Tapered (Type “D”

mod)

n/a n/a

79

79 130

156 174 271 288 646 654 716 1023 1254

Balance - Reduced

n/a n/a

n/a

33

79

91

100 125 134 156 167 188 507 616

Balance - Special

n/a n/a

n/a

58

87

133 159 180 217 250 283 317 846 1044

Painting Plan Description