Factory Built Modifications

Can’t find what you are looking for? Call

1-800-ASK-4WEG

(275-4934)

Data subject to change without notice.

Parts &

Modifications

A-343

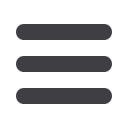

Terminal Box*

NEMA FRAME SERIES

48 56

140T 180T 210T 250T 280T 320T 360T 400T 440T

L440/

500

580

IEC FRAMES SERIES

63 UP 80 90 100/112 132 160 180 200 225 250 280 315 355

Cable Gland - Plastic

n/a n/a

10

10

14

14

22

22

22

Cable Gland - Brass

n/a n/a

33

33

50

50

182 182 182 567 567 567 567 714

Threaded Plug

n/a n/a

6

6

9

9

18

18

18

22

22

22

22

44

Terminal Block (6 pin):

n/a n/a

9

9

14

23

23

41

41

197 197 380 380 753

Additional terminal box

n/a n/a

n/a

30

30

41

41

41

41

59

59

59

70 118

Without Terminal Box

n/a n/a

18

18

22

22

33

33

33

45

45

47

58

70

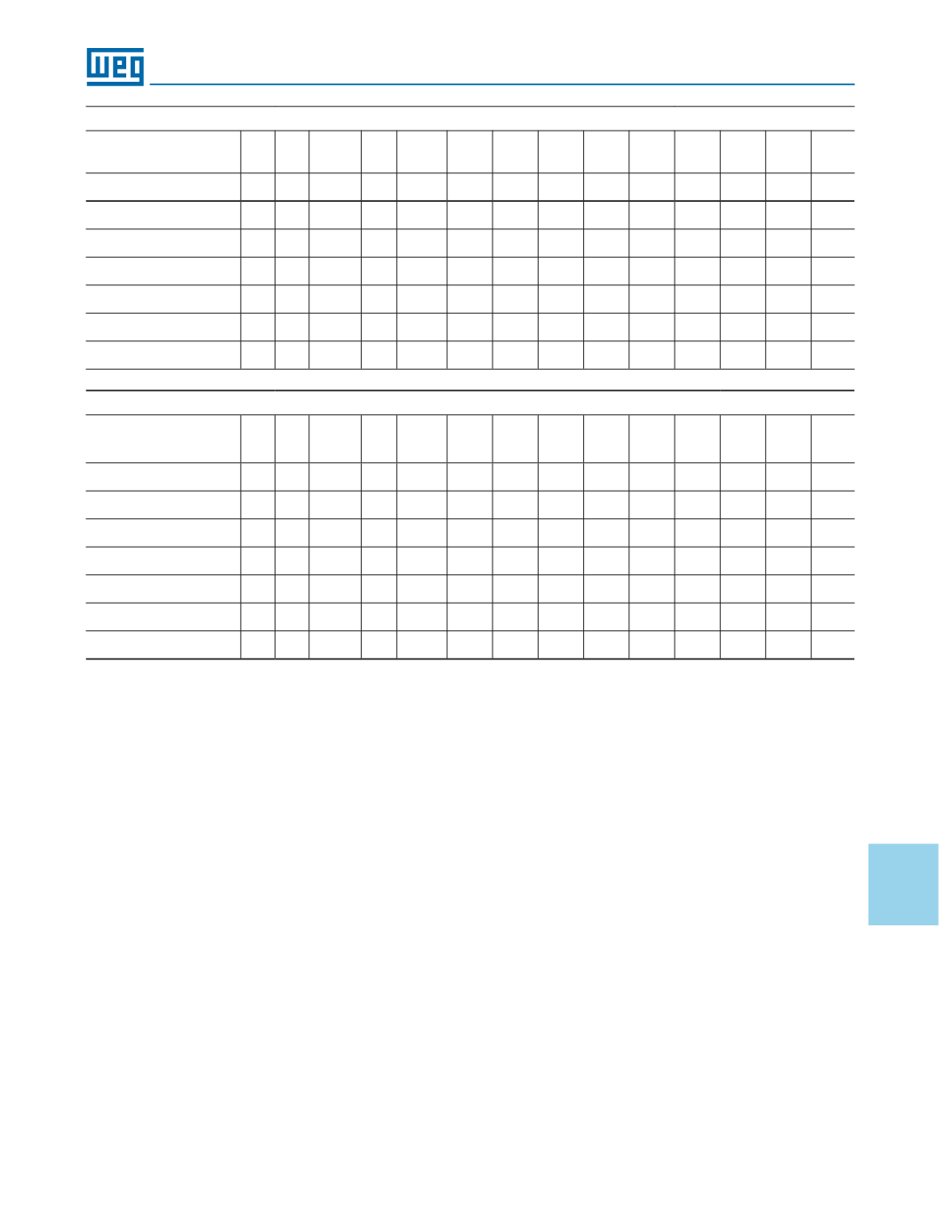

Testing:

NEMA FRAME SERIES

48 56

140T 180T 210T 250T 280T 320T 360T 400T 440T

L440/

500

380

IEC FRAMES SERIES

63 UP 80 90 100/112 132 160 180 200 225 250 280 315 355

Routine Test - Unwitnessed

381 381 381

513 513 513 513 622 622 718 877 877

Routine Test - Witnessed

1215 1215 1215 1427 1427 1427 1427 1683 1683 1903 2368 2368

Type Test - Unwitnessed

586 586 586

769 769 769 769 952 952 1208 1768 1768

Type Test - Witnessed

1419 1419 1419 1632 1632 1632 1632 1939 1939 2195 2318 2318

Vibration Test

183 183 183

205 205 205 205 285 285 403 559 559

Noise Level Test

213 213 213

242 242 242 242 322 322 462 638 638

* Not valid for Hazardous Location Motors

Routine Test

– Winding resistance check (at cold)

– Locked Rotor test (torque, current and absorbed power)

– No-load test (current and absorbed power)

– Hi-pot

– Insulation resistance

– Accessories check for continuity (if applicable)

Type Test

– Winding resistance check (at cold)

– Locked Rotor test (torque, current and absorbed power)

– Load test, including temperature rise with constant output power at

full load)

– Breakdown Torque test

– No-load test (current and absorbed power)

– Vibration test on motors 364/5T and above

– Hi-pot

– Insulation resistance

– Accessories check for continuity (if applicable)

Vibration Test

– Vibration measure on as many as 6 points, depending on the

mechanical envelope of the motor allowing access to all the

reading points

– Test performed with half key on the shaft

– Performed with motor on an elastic mounting base (rigid base

when requested)

Noise Test

– Performed at no load on an acoustic chamber

– Measurements at 1m (~ 3.3ft) distance from the motor

– Readings:

• Total sound pressure level of the motor at 4 points, in dB(A)

• Bearings sound pressure level in dB(A)

• Frequency spectrum of the global noise for the point with the most

intense reading, at 50% and 100% of rated voltage

• Frequency spectrum of the bearings noise for the point with the

most intense global reading, at 50% and 100% of rated voltage

Test Description: